We provide inspection of gas & oil worksites countrywide counting with a great quantity of highly experienced personnel.

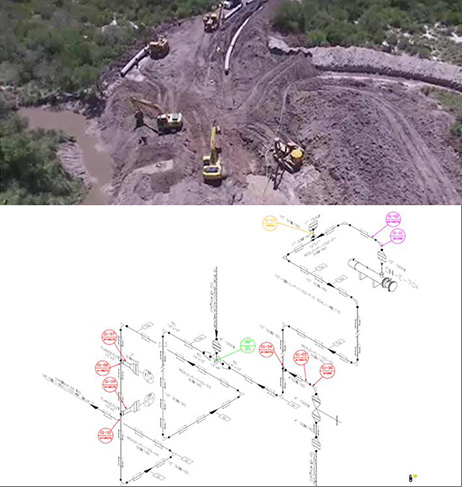

The service consists of providing field inspection including the inspection and control, materials and manufacturing in workshop, verification of anomalies in installations, development control, advance measurement and supervision of Quality/Health and Safety guidelines.

TPI

GTL provides services of Thirty Party Inspection (TPI) for tubular products and equipments/accessories for the oil & gas and petrochemical industries; manufactured under a known code, regulations or specifications by the client.

The inspection is performed during the productive process. Since the beginning of the production chain (audit to clients, incoming material, etc.) to the final testing and shipping, helping minimize the risk of obtaining as a result a product out of the standards requested by the client.

The service of TPI that we offer, which is adapted to the needs of our clients, will look after your company interests, ensuring high quality levels, saving time and costs from interruptions in the process.

INSPECTION PLANS DEVELOPMENT

Tergo Laf Group offers integral services of inspection blueprints and field survey.

In an enunciative and non-limiting nature, it stands out:

- Definition of circuits

A process, flow diagrams and corrosión mechanism study is developed, to define the circuits on which an inspection plan will be developed.

- Inspection Isometry

An integral P&ID, Piping Class and 3D model study is done for the isometric blueprints realization and location of the inspection points, using for this purpose a CAD software.

- Base 0 field measurement

With the bluprints done a field survey is developed to obtain the inicial thickness by the use of non destructive techniques o xray.

With this you achieve:

- Control of the initial thickness,

- Control of the de deviations in the manufacturing process,

- Set the correct bases for future integrity computation of the assets.

WELDING INSPECTION

<<Under construction>>

Certified Inspection

Tergo Laf Group offers services of field inspection, quality personnel, certified in the main aspects.

API 570: covers the procedures of inspection, repair, alteration and re-classification for metallic pipe systems on service.

API 510: pressure vessels inspection: inspection, repair, alteration and computation of pressure vessels on service.

API 653: Inspection on tanks, repair, modification and reconstruction.

Also, as part of the assuring and quality control, Tergo Laf Group provides the service of QAQC inspectors for plants, in the specialties of mechanical, electrical & instruments and piping.

Mechanical Inspector: specifications managing, codes and standards, both national and international. Knowledge in leveling, aligning and start up of rotatory equipments. Knowledge of inspection of static/pressure equipment, welding inspection, dimensional verification, hydraulic tests.

Inspector E&I: specifications managing, codes and standards, both national and international. Knowledge in electrical engines, transformers, low and medium voltage cells, PLC, Sub Stations, etc.

Piping Inspector: specifications managing, codes and standards, both national and international. Knowledge in piping inspection, non destructive testing, pressure tests, isometry and P&ID, painting. Knowledge in valves testing and inspection of materials such as spouts, accessories, joints, valves, etc.