Solutions that combine know-how, technology and compromise for our clients to know, in a 100% trustworthy manner, the true state of their pipes.

GTL, I want them on my team!

Strategy & Adaptation

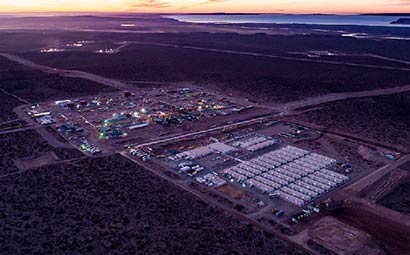

The conventional energy sources continue to be essential for the development of modern societies. In this context, the oil & gas sector plays a strategic role in medium and long term. Tergo Laf Group offers the most modern technologies to optimize your times and resources and the greatest flexibility to quickly and efficiently answer in the assembly of specialized teams that guarantee the total coverage of remote territories countrywide.

Qualification and Certification Entity

Integrated management system to perform the Qualification of Welders and Welding Operators, their corresponding certification and the Development and Qualification of Welding Procedures according to ASME, API, AWS, among others.

Training

The professionalism and specialization of the resources is what differentiate Tergo Laf Group teams. “We do things properly since the beginning, to sustain our compromise until the end”.

IRAM-ISO 9001:2015 Certification

TERGO LAF GROUP S.R.L. has a quality management system that meets the requirements of the IRAM – ISO 9001: 2015 standard, whose scope is:

- Conventional and non-conventional non-destructive testing services.

- Inspection and survey services for facilities, pipelines, equipment and works.

- Structural mechanical integrity services.

- Development and qualification of welding procedures, qualification and certification of welders and welding operators

The Quality Management system is a tool that has allowed us to carry out activities in an organized manner, with greater efficiency, meeting high quality standards achieved thanks to the process of continuous improvement in all our processes.

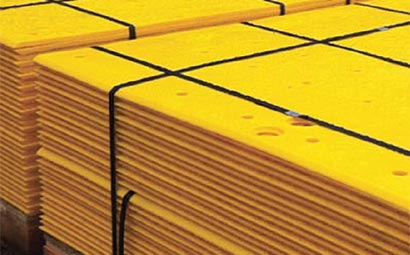

Asset Integrity Management

Pipelines, process plants, pressure vessels, storage tanks, field facilities and offshore.

Qualification and Certification Entity for Welders, Welding Operators and Welding Procedures

• Qualification of Welders and Welding Operators and their corresponding certifications.

• Development and Qualification of Welding Procedures according to ASME, API, AWS, among others.